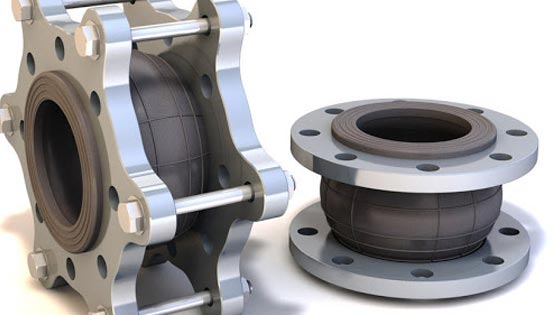

Rubber expansion joints are used widely in most energy and industrial plants today. Made from natural or synthetic elastomers, rubber expansion joints are vital components used as flexible connectors in which special fabrics are embedded to provide physical reinforcement. They are used in a variety of applications. Rubber expansion joints are available in standard sizes or customized to the customer's individual needs from a variety of high quality synthetic rubber materials.

What are Rubber Expansion Joints?

Rubber Expansion Joints are defined as connectors between vessels or used in all systems transporting fluids, slurries or gases operating under pressure at widely different temperatures. These rubber expansion joints are installed in air and gas duct systems in all power plants, gas turbine systems, diesel engine installations, petrochemical and chemical plants, pump systems, cement works, steel works, incinerators, on- and offshore systems, ships and cruise vessels, etc.

Uses of Rubber Expansion Joints

In a relatively short space, rubber expansion joints provide the ultimate solution to:- Compensate for pipe misalignment

- Absorb compression and extension

- Accommodate pressure loads

- Reduce noise

- Isolate vibration

- Neutralize axial, lateral, angular stresses

- Prolong life of motive equipment

- Prevent damage to pipe-work or ducting system

- Relieve stress of on equipment flanges

- Adjust for seismic movement

Applications of rubber expansion joints

HVAC Applications

Rubber expansion joints are used in a variety of heating, ventilation, and air conditioning systems, which includes commercial and industrial buildings, hotels, apartments, schools, shopping plazas and aboard ships to relieve stress in ductwork. Rubber expansion joints are installed to isolate equipment like pumps, compressors and chillers from the piping system. A variety of configurations of joints are available accommodating different shapes, service and connection requirements.

Process Piping

Protection of a process piping system is an important use for rubber

expansion joints. The joints reduce noise and vibration caused by forces in

pumps. They also centrifuges by behaving as a shock absorber in systems

handling abrasive slurries, corrosive chemicals, or very reactive liquids or

gases. Thermal movement in a piping system can also be avoided by using

rubber joints. The excellent chemical resistance of rubber and synthetic

elastomers make these joints ideal for process piping systems.

Power Plant Applications

Nuclear and fossil fuel plants use Rubber expansion joints so as to reduce

thermal expansion and contraction on condenser lines, condensate lines,

steam turbine exhaust lines, aeration systems and cooling water lines.

Reliability, large size capability, long life, and the ease with which they

accommodate themselves to movements make these expansion joints ideal for

power plant applications.

Industrial Ducting Systems

Rubber expansion joints have been installed in demanding industrial ducting

systems where there are problems like heavy vibration, dry or wet corrosive

materials, flutter etc.

Marine Systems

Eliminating the destructiveness of electrolysis and at the same time

insulating against the transmission of sound, rubber expansion joints allow

the necessary motion and flexibility in a 'moving' ship's piping system. The

compactness, resilience and low stress features of rubber make these joints

ideally suited for shipboard piping systems. The rubber joints are popularly

used in areas like auxiliary condenser, air intake on diesel engines,

overboard discharge line between condenser and hull, ventilation lines,

flush and sanitary systems, fire and bilge pumps, to name a few.

Pollution and Wastewater Treatment

Water treatment plants, waster water treatment plants, Sewage treatment

plants, and air scrubber systems all employ the use of rubber expansion

joints. Due to their resistance to abrasion and corrosion as well as their

flexibility feature, rubber expansion joints are ideal to be used in raw and

secondary sewage lines, sludge pumps, centrifugal air blowers, scrub stacks.

- Anti Vibration Mountings

- Automobile Rubber Products

- Calendered Rubber Products

- Extruded Rubber Products

- Medical Rubber Products

- Metal Bonded Components

- Rubber Adhesives & Sealants

- Rubber Ball

- Rubber Bands

- Rubber Beading

- Rubber Bearing

- Rubber Belt

- Rubber Buckets

- Rubber Bullets

- Rubber Cable

- Rubber Coating

- Rubber Duct

- Rubber Expansion Joints

- Rubber Flooring/Matting

- Rubber Footwear

- Rubber Gloves

- Rubber Injection Parts

- Rubber Lining

- Rubber Magnets

- Rubber Molded Products

- Rubber Pads

- Rubber Rollers

- Rubber Stopper

- Rubber Suit

- Rubber Track

- Rubber Valve

- Rubber Balloon

- Rubber Stamps

- Rubber Fenders

- Acrylic Rubber (ACM)

- Butadiene Rubber (BR)

- Butyl Rubber (IIR)

- Chlorosulfonated Polyethylene(CSM)/ Hypalon

- Ethylene Propylene Diene Monomer

- Fluoroelastomers (FKM)/Viton

- Isoprene Rubber (IR)

- Nitrile Rubber (NBR)

- Perfluoroelastomer (FFKM)

- Polychloroprene (CR)/Neoprene

- Polysulfide Rubber (PSR)

- Silicone Rubber (SiR)

- Styrene Butadiene Rubber

How to Make a Custom Rubber Stamp?

Whenever designing a custom stamp for your company, never compromise on its quality because in the end it is the most...

Read MoreLatex and Silicone Rubber Tubing - A Comparison!

Many industries use rubber tubing for various purposes. In fact, various types of rubber tubing are used for different applications...

Read MoreSilicone vs Acrylic Adhesive- A Comparison

Silicon and acrylic adhesives are those rubber adhesives that are widely used in Polyimide tapes. In fact, the polyimide...

Read More