Rubber to metal bonding is defined as a process covering a number of interdependent processes, in which rubber is adhered to metal substrate. Today, various factors concerning environment have an impact on all aspects of commerce and industry. Rubber to metal bonding is no exception and the process is undergoing changes to reflect these concerns. Because of the several parts used today consisting of bonded rubber to metal, there are various custom shops who specialize in the manufacturing of these parts and they work with customers from the design level through production.

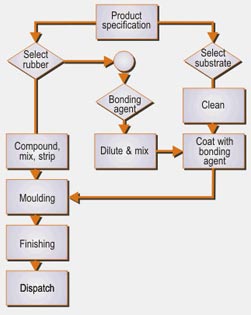

The Rubber Bonding ProcessThe rubber can be molded to a metal piece. It can also be adhered to a metal piece.

The rubber to metal bonding process involves three elements:

- Rubber

- The bonding agent

- The substrate

Any type of rubber can be used but usually the selection of the polymer base and its related compound depends on the product specification. The condition is that the rubber should easily flow into the mold without developing a significant level of cross-linking, and thereby a bond can be created using any rubber compound. It is also advised to avoid substances that will bleed rapidly to the surface of the uncured stock. Before the molding takes place, the metal is made completely free from rust and other impurities by degreasing, sandblasting or shot blasting. The bonding agents comprises polymer/solvent solutions, having a primer coat related to phenolic-style resins and a topcoat of polymers and other materials. Usually the solutions used are patented. The substrate used depends on the strength and durability requirements of the application.

Science Behind the Rubber to Metal Bonding Process

The science behind this process is very complex as well as varied. Often the type of rubber or polymer used depends on what type of metal is used and the part that is to be manufactured. Determining the appropriate bonding agent is very important. The selection process depends on three factors:

- Rubber to be used

- The elasticity of the rubber

- The component design

Originally, the metal used was steel in all its forms and grades. Steel is still in use but increasing use is also made of aluminum alloys and polyamides. Any material can be bonded to rubber, the only condition is that that it can bear the heat and pressures of the rubber molding process. However, the results of bonding rubber to alloys, like brass, bronze depend a lot on the composition of the alloys.

Applications of Rubber to Metal Bonding Units

The products made from the bonding of rubber to metal are used in various areas of the medical, commercial and industrial fields. Many of the products are used for the isolation of vibration and noise in manufacturing applications, including automotive and engineering applications. Larger sized pieces are used to decouple translational movement for bridges and buildings.

There are various products made out of the rubber to metal bonding process like:

- Gaskets: Gaskets are a type of seal made often with bonded to metal rubber.

- O-rings: These rings to seal rotating or sliding shafts are often made with a rubber coating on metal, are used widely in applications like shock absorbers and differentials.

- Piping:Piping is often bonded with rubber when the pipe line is required to be vibration absorbent and more insulated.

- Press bonding:This refers to a non-heat or chemical process of bonding rubber to metal, involving the bonding of a preformed rubber piece onto metal piece by a predetermined groove or space and a mild adhesive agent.

- Rubber rollers: Used to squeeze water out of pulp in paper manufacturing, the roll has a metal core lined with rubber to perform efficiently.

- Seals: Often used as shut off pieces in hydraulic equipment, seals are the most common types of products formed with rubber bonding technology.

Rubber Metal Bonded Components in Automobile Industry

The automobile industry, in particular uses a large number of bonded rubber to metal parts. Some of these products are:

- The Steering Wheel: The is joined to the steering column by various rubber bonded parts.

- Foot Pedals and Bumpers: These items that have rubber/metal characteristics.

- The Engine and Gearbox Units: They are usually mounted on a rubber bonded unit.

- The Strut Units: These units mount the wheels to the vehicle chassis by using a shear style rubber bonded bush.

- Anti Vibration Mountings

- Automobile Rubber Products

- Calendered Rubber Products

- Extruded Rubber Products

- Medical Rubber Products

- Metal Bonded Components

- Rubber Adhesives & Sealants

- Rubber Ball

- Rubber Bands

- Rubber Beading

- Rubber Bearing

- Rubber Belt

- Rubber Buckets

- Rubber Bullets

- Rubber Cable

- Rubber Coating

- Rubber Duct

- Rubber Expansion Joints

- Rubber Flooring/Matting

- Rubber Footwear

- Rubber Gloves

- Rubber Injection Parts

- Rubber Lining

- Rubber Magnets

- Rubber Molded Products

- Rubber Pads

- Rubber Rollers

- Rubber Stopper

- Rubber Suit

- Rubber Track

- Rubber Valve

- Rubber Balloon

- Rubber Stamps

- Rubber Fenders

- Acrylic Rubber (ACM)

- Butadiene Rubber (BR)

- Butyl Rubber (IIR)

- Chlorosulfonated Polyethylene(CSM)/ Hypalon

- Ethylene Propylene Diene Monomer

- Fluoroelastomers (FKM)/Viton

- Isoprene Rubber (IR)

- Nitrile Rubber (NBR)

- Perfluoroelastomer (FFKM)

- Polychloroprene (CR)/Neoprene

- Polysulfide Rubber (PSR)

- Silicone Rubber (SiR)

- Styrene Butadiene Rubber

How to Make a Custom Rubber Stamp?

Whenever designing a custom stamp for your company, never compromise on its quality because in the end it is the most...

Read MoreLatex and Silicone Rubber Tubing - A Comparison!

Many industries use rubber tubing for various purposes. In fact, various types of rubber tubing are used for different applications...

Read MoreSilicone vs Acrylic Adhesive- A Comparison

Silicon and acrylic adhesives are those rubber adhesives that are widely used in Polyimide tapes. In fact, the polyimide...

Read More